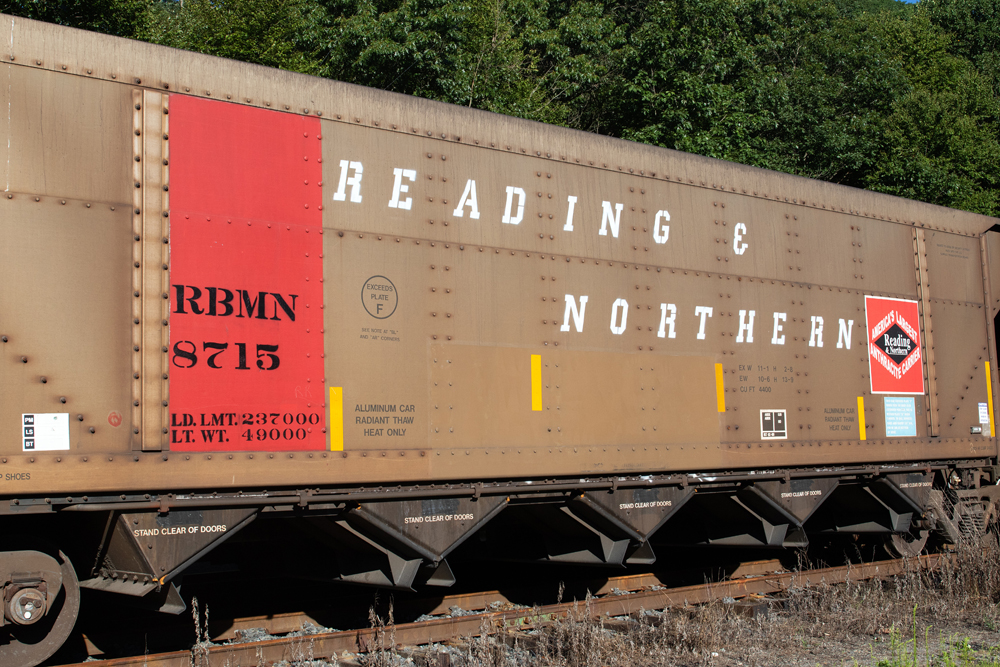

PORT CLINTON, Pa. — Reading & Northern Railroad has shipped more than 1 million tons of anthracite coal for the third straight year, the company announced on Dec. 31.

That figure came despite a downturn in export volume, the railroad said in a press release, thanks to the domestic market that mainly supports U.S. steel production. The railroad’s domestic anthracite traffic grew nearly 20% in 2025, with most shipments going to electric-arc furnace steel mills across the country. To support the traffic, the railroad purchased additional hoppers in mid-December that are expected to be delivered in January or February 2026. They will join R&N’s fleet of more than 2,000 railcars, and the railroad anticipates purchasing additional equipment to meet the demand.

Overall, the railroad expects to move more than 40,000 carloads in 2026.

R&N first reached the 1-million-ton mark in 2023 [see “Reading & Northern hits one million tons …,” Trains.com, Dec. 11, 2023].

In a subsequent release, the railroad said it posted record freight revenues and passenger ridership in 2025. Freight traffic showed modest growth, including a 2,000-carload increase in frac sand traffic, as well as carload and revenue success with movement of plastic resins, forest products, and food and agricultural commodities. The R&N spent more than $8 million to support this traffic through purchase of 117 freight cars, vehicles and track equipment, and track and signal materials, the company said. Passenger operations saw excursion ridership top 400,000 for the first time.

“Thanks to our customer-focused staff, R&N continues to enjoy growth year after year,” CEO Andy Muller Jr. said. “We continue to invest in our railroad to make sure we bring first-class service to our freight customers and our passenger riders. Reading & Northern will continue to thrive and work with our communities and neighbors to expand our offerings.”

— Updated Jan. 6 at 7:25 p.m. CT with additional information. To report news or errors, contact trainsnewswire@firecrown.com.

1 million + tons would equal 10,000+ car loads

Someone could probably write plenty on how the Electric-Arc furnace changed/impacted the rail industry in itself let alone steel production.

..

For one, I believe most of Electric Arc furnaces where built entirely new in new locations more southerly & along inland waterways vs steel production being northerly on or closer to Great Lakes. So instead of US Steel replacing Granite City, IL furnace you end up with a large new massive Arc Furnace & ever expanding facility to the south in Arkansas. Second, Believe most of the Electric Arc furnaces take a considerable more scrap metal as significant aspect of the feedstock from my understanding. So lot less ore and limestone (used to process iron ore pellets) coming into and or off the Great Lakes ships, and so on.

..

Sure everyone else can think of multiple other changes but adding up to the point where a regional rail becomes a significant rail car owner to get a specific product across the US. Just one more example on why Reading & Northern is top notch

I am not 100% sure why, but seeing anthracite being hauled in aluminum hoppers seems incongruous to me. Maybe it is because I associate anthracite with home heating coal, something that started to fade away around the same time steam locomotives were replaced with diesels, whereas aluminum hoppers seem more at home as a string of 100+ cars behind Dash 9’s.