In this article we’ll look at five ways to clean track. If you want to get a lively debate started amongst model railroaders, ask them the best way to clean track. Some prefer abrasive blocks, like the Bright Boy, while others turn to any number of cleaning solvents, homemade or commercial cleaning cars, or off-the-shelf cleaning systems. Which one is the best? That’s a matter of personal preference.

Abrasive blocks

An abrasive cleaning block is a popular method for cleaning track. The Walthers SceneMaster Bright Boy has long been a popular choice for modelers. Similar blocks are produced by Atlas Model Railroad Co. and Peco.

In “Tune up your layout, Part one: Cleaning track and adjusting rolling stock” (May 2007 Model Railroader, pp. 42-45), veteran modeler Paul J. Dolkos wrote, “I reserve abrasive materials for only occasional heavy-duty cleaning. And whether you use sandpaper or a Bright Boy, avoid those that are extra coarse. These will scratch the rails instead of polishing them. Dirt and dust tend to collect in these scratches, making it more difficult to keep the rails clean.”

In place of coarse cleaning blocks, Paul prefers an extra-fine Cratex block, such as Walthers No. 949-522. He also uses strips of basswood to clean tracks. The wood is strong enough to remove grime but soft enough not to scratch the rails.

Cleaning solvents

When I searched “track cleaner” on the Walthers website, I was surprised at the number of cleaning solvents on the market today. Among the offerings were:

- Atlas Model Railroad Co. track cleaning fluid [https://shop.atlasrr.com/p-50-act-6226pl-track-cleaner-1oz.aspx]

- Bachman Rail & Road track cleaner liquid

- Deluxe Materials Ltd. Track Magic liquid track cleaner

- Excelle Lubricants Rail Conditioning Fluid

- Labelle Industries No. 105 track conditioner

- Robart Manufacturing Inc. Rail-Zip track cleaning fluid

- Woodland Scenics Clean Track Solution

Though all of the products have the same goal, keeping track clean, the application process and frequency may vary. Read the instructions carefully and follow all manufacturer recommended safety precautions.

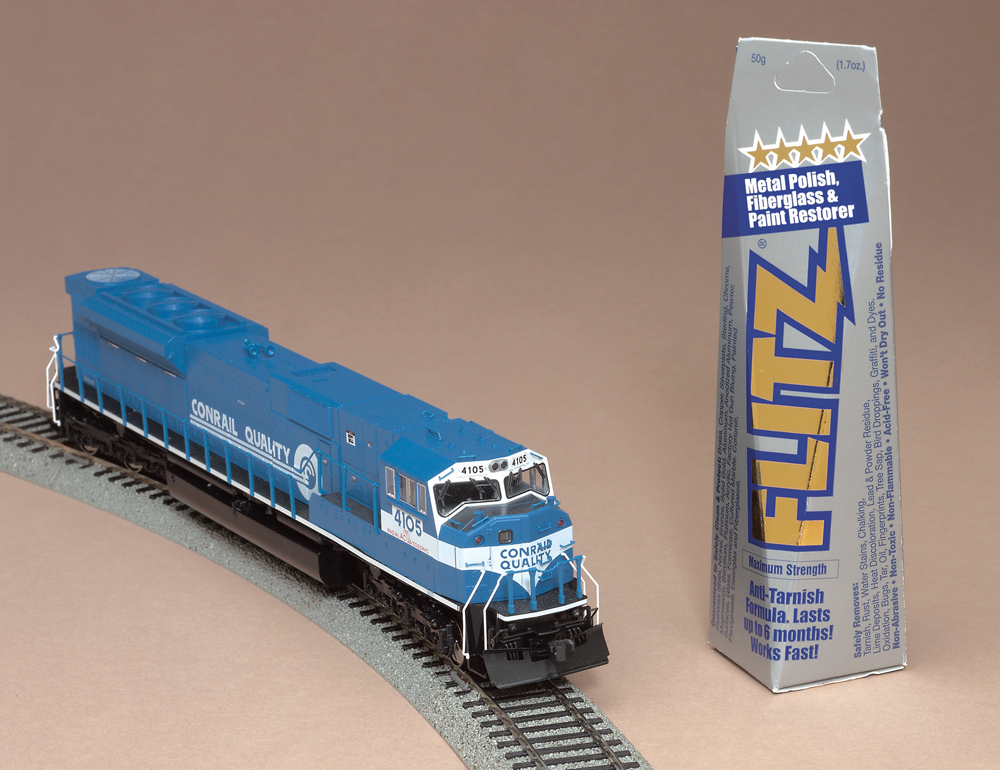

In the January 2003 issue, we ran Glen Scholey’s article “Polish those railheads!” In the article, Glen explained how he used metal polish to clean the rails on his model railroad. Glen turned to MAAS Polishing Creme for his layout, but the article also referenced Flitz metal, plastic, and fiberglass polish from Miracle Group Inc.

The Flitz packaging notes that the anti-tarnish formula lasts up to six months. Glen stated in his article, “Our experience has shown that cleaning the rails with metal polish is preferable to an abrasive track cleaner, with the added benefit that the polish significantly slows the buildup of oxidation.”

Cleaning cars

There have been a variety of wet and dry track cleaning cars produced over the years. Bachmann Industries offers an HO scale steam-to-diesel transition era single-dome tank car with a weighted, pivoted reusable pad between the trucks. The car can be used on straight track, turnouts, and curves.

To see a video of the car in action, visit the Trains.com website. To purchase the car, visit the Kalmbach Hobby Store website.

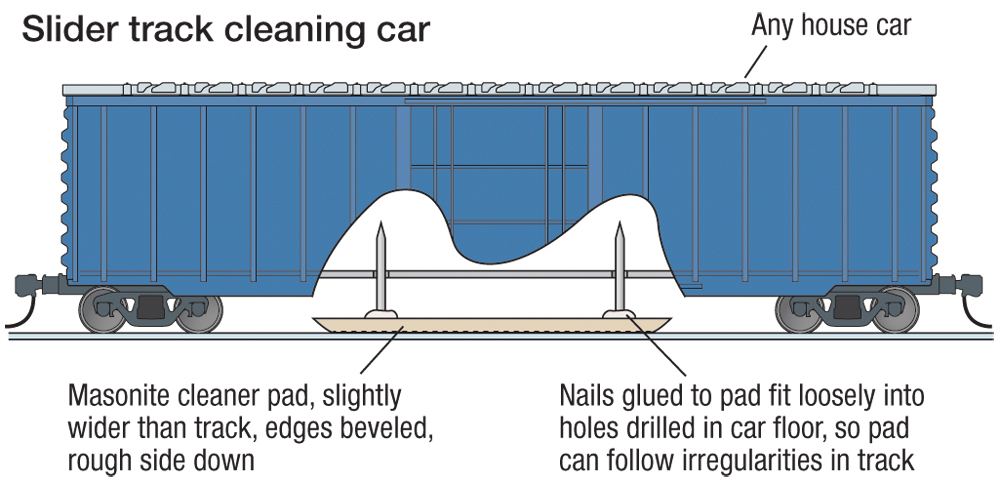

If you’re more the do-it-yourself type, you can make your own cleaning car using a method developed by the late John Allen, builder of the well-known HO scale Gorre & Daphetid. John attached a tempered hardboard pad, rough side down, to two nails with glue. The nails fit into holes that he drilled in the bottom of a boxcar. This allowed the pad to float in the underbody, reducing the chances it would snag on turnouts, crossings, or track irregularities. He cut the pad slightly wider than the track and beveled both ends.

To learn how to build a car like this, check out Trains.com contributing editor Gerry Leone’s video “Make a track-cleaning car”.

A-Line produces a kit with components to make a tempered hardboard cleaning pad designed to fit an HO scale 40-foot boxcar. You can purchase the kit through the Kalmbach Hobby Store.

Cleaning systems

If you’re looking for an all-in-one cleaning solution, you’ll want to take a look at the Woodland Scenics Rail Tracker cleaning kit, part of the company’s Tidy Track line. The kit includes the Rail Tracker tool, a 12” handle, an .85 fluid ounce bottle of Clean Track Solution, two each maintenance and rescue pads, and four each cleaning and finishing pads.

The pads included with the Rail Tracker are compatible with N, HO, and three-rail O gauge track. The handle fits into the Rail Tracker, allowing the track cleaning tool to reach into tunnels, under bridges, and other places where our full-size hands won’t fit. The handle pivots 180 degrees, handy for curved track sections. The manufacturer recommends locking the head when cleaning turnouts.

You can read a full review of the Rail Tracker on our website. You can purchase the track cleaning system on the Kalmbach Hobby Store website.

Thinking outside the box

We’ll wrap up our look at five ways to clean track with an outside-the-box technique. In the May 2011 issue, Steve Carter of the Puget Sound Model Railroad Engineers in Tacoma, Wash., reported on how the club experimented with transmission fluid (ATF).

The group found that ATF improved electrical contact on its HO scale layout. A small application once per week helped trains run smoothly on the club’s 25 x 95-foot model railroad. They found there was a slight loss of traction on a 2 percent grade. To work around that issue, the club shortened its train length by two cars.

I hope you’ve enjoyed this rundown of five ways to clean track. Give these methods a try and see which one works best for you.

Another “out of the box” solution is what I use: a carbon block. A carbon block is what an artists who does pencils uses. I find that it not only cleans the rails, but leaves a very thin layer of carbon on the rails, so that even if they start to get dirty, it will still conduct electricity.